Top Grade Raw Materials

When it comes to product quality, raw materials play a critical role. Meraaki Ceramiche understands this concept very well, which is

why we only use the highest quality, finest raw materials such as clay, calcium silicate slag, and others to produce the best ceramic tiles in the

industry. All of the raw materials we use are sourced from places known for producing high-quality ceramic raw materials.

When these materials arrive, they are thoroughly inspected and tested by a third-party lab. Furthermore, these raw materials are only used in production

if all of the quality checks are passed. All of this effort and process is done solely to ensure that we produce and supply high-quality ceramic

products worldwide. Ultimately, when you buy tiles from Meraaki Ceramiche, you can be certain of their quality.

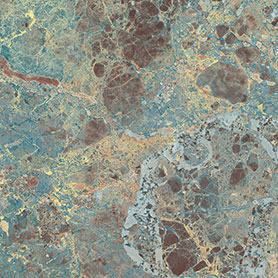

Advanced Technology

In addition to high-quality raw materials, we use cutting-edge technologies in the manufacturing process. These state-of-the-art technologies

enable us to create high-quality ceramic products with sophisticated designs and greater realism.Moreover, the advanced technological support

also enables us to take ceramic products to new heights and broaden our product offering.

Furthermore, we have an advanced printing technology infrastructure that allows us to create unique patterns, designs, and vibrant colors on individual

tiles, much like natural materials. Not only does this cutting-edge technology infrastructure allow us to produce tiles with striking designs and patterns, but it also allows us to produce tiles with higher durability, scratch resistance, and wear and tear strength. Overall, our cutting-edge technology

infrastructure enables us to produce the best and stay ahead of our competitors.

System Digital Printing

Machine With 12 Heads

Italian ingenuity has developed breakthrough digital printing machines expected to revolutionise ceramic tile production. Cutting edge digital glazing and decoration technologies provide unprecedented levels of efficiency and creativity for cheaper, healthier and print some beautiful and gorgeous designs on tiles to make contemporary and stylish way.

Stringent Quality Inspection

Quality inspection is an important part of the manufacturing process when it comes to ceramic tiles or any other product. Our technological advancement also includes machinery that allows us to check every parameter of ceramic products to ensure that they meet the expected quality standards. Our quality experts examine every product from each manufacturing lot and conduct a series of tests, including abrasion resistance, water absorption rate, chemical resistance, frost resistance, linear coefficient of thermal expansion, and slip resistance tests, among others.

Not to mention that all ceramic tiles and other ceramic products must pass all of these quality checks before leaving our manufacturing facility. If a product fails any of these tests, it will not be allowed to leave the manufacturing unit and will be destroyed there. All of this demonstrates how seriously we take quality at Meraaki Ceramiche.

Pallet Packaging

Since we ship our high-quality ceramic tiles all over the world, and because tiles are a brittle product, it's important to properly pack them to ensure they arrive at their destination safely and undamaged. Meraaki Ceramiche uses pallet packaging in most cases to achieve this goal.

On-time Dispatch

Your time is extremely valuable to us. Meraaki Ceramiche makes certain that all orders are pallet packed and shipped on time, with no unnecessary delays. Your order will be processed as soon as we have completed all of the necessary steps.